Cutting and drilling concrete efficiently require proper drill or blades. Having these has become a challenge considering the huge array of materials used for commercial and domestic projects. This applies to both contractors and the do-it-yourself enthusiasts as well.

Drilling

Traditionally, drill bits are made of steel. Low and soft carbon steel bits, however, can only be used for drilling wood.

On the other hand, high-speed steel bits or HSS can be used to drill an array of materials including concrete, metal as well as hardwood. That’s because they use higher speeds than conventional steel bits. For extra hard materials, cobalt steel alloys are ideal for drill bits.

Tungsten Carbide and other types of carbide are very hard and can drill almost any challenging material including concrete while retaining their edge. Sadly, they are very expensive and can be brittle.

For this, there are coatings like Titanium Nitride, Black Oxide, Zirconium Nitride and Titanium Aluminium Nitride that can be applied to drilling bits that extend the life of the machine and provide greater heat resistance. Among these perhaps the most useful of all is diamond powder, providing a durable, long-lasting solution to concrete drilling.

A diamond cutter or drill generates a lot of heat. Don’t not allow this to build up. Excess heat may damage some materials and finishes. Fortunately, some diamond drills come with water-cooled wet cores that provide a continuous stream of coolants for the drilling materials such as limestone aggregate concrete and reinforced concrete.

A conventional dry core diamond drill is perfect for soft to medium bricks, abrasive concrete products, and concrete blocks. A super fast and tougher dry core drill is more suited for harder building materials but can take on any material. From clay products, limestone aggregate concrete to engineering bricks.

Cutting Saws

There are numerous types of cutting saws, but we’ll look at the circular kind.

If you are looking to cut stone and ceramic tiles or floors, look for tile cutting blades. Such blades can get in the hard surface and give you a clean and well-finished hole. For other types of floor materials like asphalt and concrete, look for specialized floor saw blades.

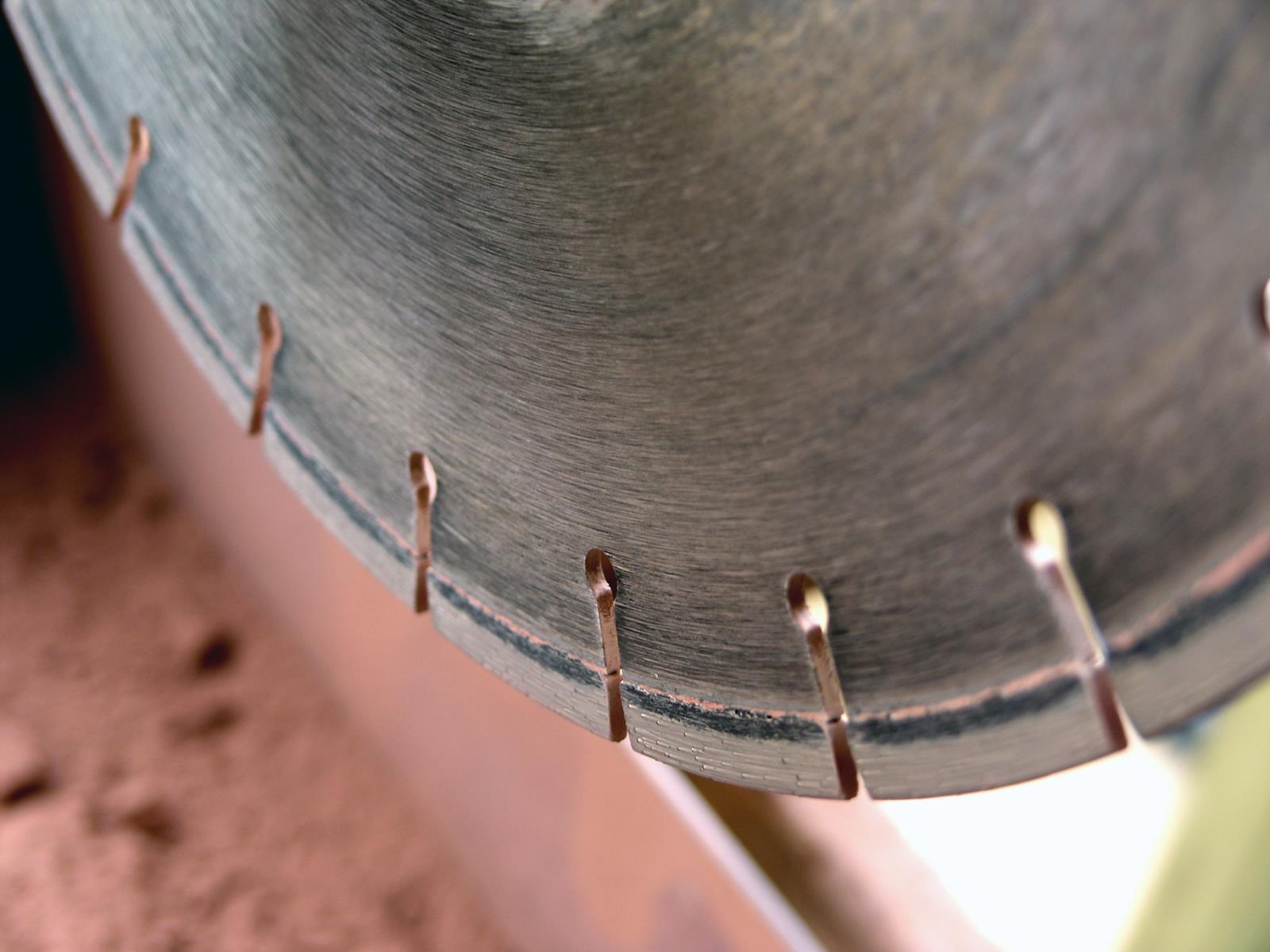

If you are looking to cut building materials such as concrete, engineering bricks and clay substances, go for a segmented universal or hard diamond blade with cooling holes (for heat dispersal). On the other hand, if you want to cut natural stone, a high-quality super-fast blade should be the best option.

For wood, a reliable tungsten carbide tipped, or high-speed steel blade should be ideal. For more demanding projects, you may want to consider purchasing more advanced blades, lest you end up with a product that can’t do you any good, or soon overheat and get blunt.

Diamond tipping allows manufacturers to provide an array of blades that are specific to the requirements of cutting some materials. Generally, a standard diamond blade can handle the demands of cutting concrete paviors, tiles, slabs, bricks and other concrete materials.

Regardless of what you need to cut or drill, make sure that the drill or blade suits the material. It makes the work easier, saves you money by lasting longer and gives a better finish.

Leave A Comment