When engaging in diamond grinding, the first question a person must ask themselves is what to expect from their diamond wheel. The ideal diamond wheel should be one that removes carbide from the diamond in a fast and cool manner. This is a factor that must be considered carefully when purchasing a diamond wheel to ensure you find a wheel that will last a long time.

In this false economy, it is possible that you could pay a great deal of money for a poor diamond wheel; however, with the correct knowledge, you will be able to purchase a wheel that is good value for money. This article will provide information on diamond grinding and be a successful diamond grinder.

One issue that needs to be considered when purchasing a diamond wheel is the cost of the wheel, and the way of arriving at the overall cost is to add the wheel cost with the cost of the grinder labour. It is important to remember that there is no point of return once a wheel has been used too much for diamond grinding as this affects its lifespan. To determine the cost, it is necessary to take into account specific economics and look at the labour on a wheel according to the dollar volume of work. For example, if one grinds one saw for $10 in fifteen minutes using £2 worth of diamonds, you will be better off than grinding the same amount in thirty minutes with only $1 worth of diamonds.

Another issue that needs to be considered when purchasing a diamond wheel is the use of diamonds as part of the grind carbide. This requires the identification of a successful balance between labour costs and diamonds to give you the ideal return on your investment. Remember that labour costs are the more costly aspect of the diamond grinding job and need to be examined closely.

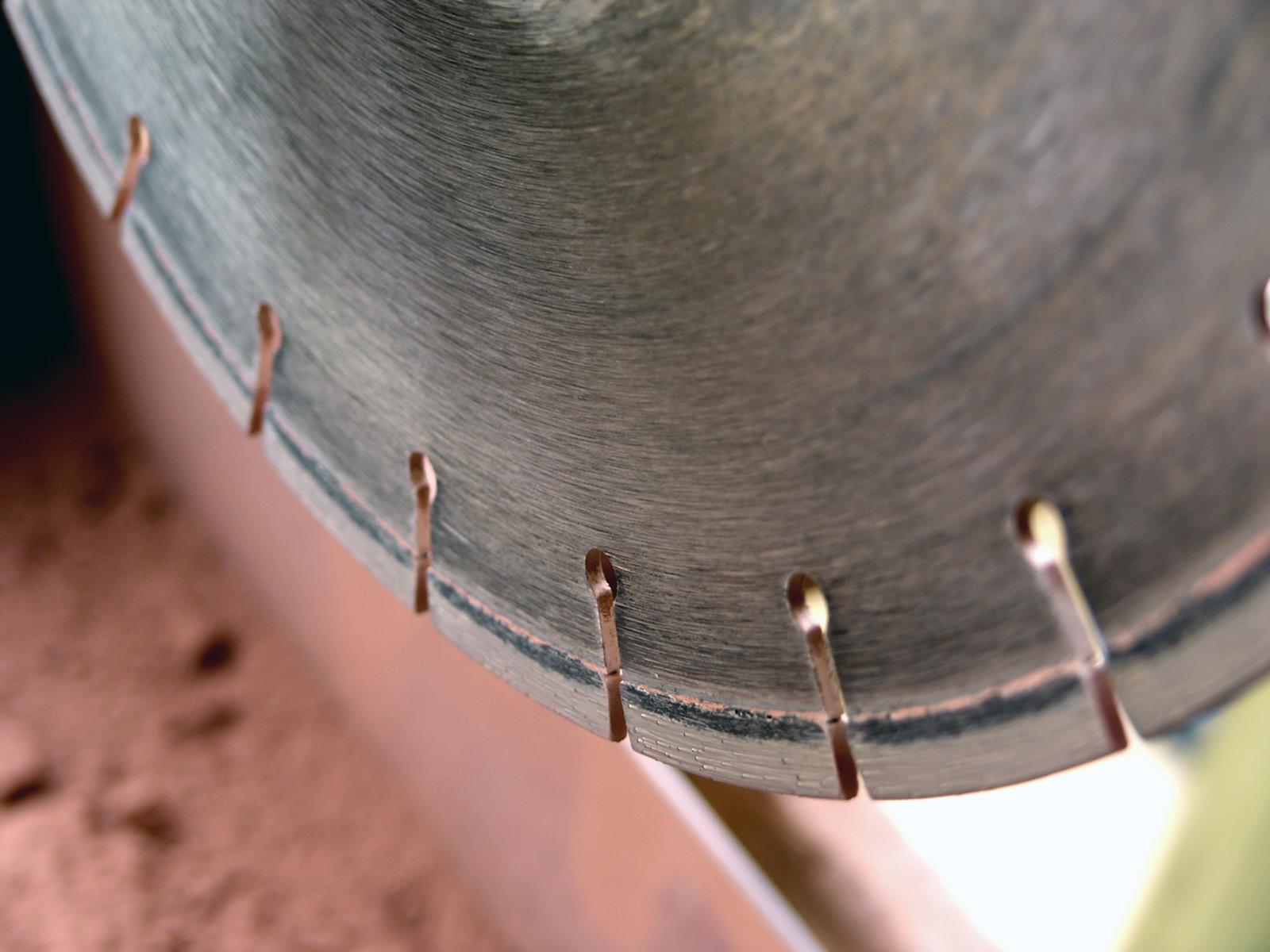

Almost 50 years ago, diamonds were first seen on the market and since then the diamond industry has grown dramatically. Nowadays, the manufactured diamond presents a uniform style, size, and resistance when compared with the natural diamond counterparts. Of course, the lifespan of diamonds is enhanced using a coating of the stones with copper and nickel. This makes the diamond last longer, but to achieve such a result it is necessary for extensive diamond grinders and the use of more grinding heat. Plain diamonds are cooler, however than the nickel-coated diamonds that are most suitable for wet grinding.

The bonding of diamonds is available in two separate styles using either resinoid or metal bond types. The metal bonds are effective on non-metallic materials such as stone or ceramic, but they are not highly efficient when grinding on carbide. This is due to the fact that bonds are too hard for carbide grinding.

Resin bonding is available in various grades and hardness by diamond grinders, and diamonds are available in various grades with different levels of coarseness. When selecting a diamond wheel, it is important that you consider the operation and choose the wheel best suited to the needs. Typically, wheels will present with 150 grit, 75 concentration, and R hardness.

Finer diamond wheels tend to provide better finishes than regular wheels on the carbide; thereby, improving the quality of the diamond’s cut and lengthening the life between sharpening. Despite the wheel also requiring less power, it does grind more slowly and will require extra time to complete a saw. Once again, you will need to be the judge of your grinding and your customer’s diamond requirements to choose the best wheel.

Creating a diamond is important, so it is necessary to consider the diamond located within the wheel as well. An increase in a diamond of approximately 125% will improve the wheel’s grinding performance, but any wheels with 50% or lower concentration will be poor performers. This type of wheel should be avoided as it is a poor purchase.

Arguably, the most important factors to consider when choosing a good diamond grinder are the wheel speed with the traverse rate. The variables can greatly influence the cost and must be examined carefully to avoid a poor investment.

Leave A Comment